Empowering the SDLC with Tools to Bridge R&D and QA Teams

In the complex world of medical device development, the gap between Research and Development (R&D) and Quality Assurance (QA) teams can often lead to significant challenges. Medical device manufacturers must ensure their innovative products meet stringent regulatory requirements.

In this webinar, Andrew Wu from Rook Quality Systems and Jake Stowe from Ketryx provide actionable insights and best practices to help bridge this gap, ensuring smoother FDA processes and higher-quality medical devices.

Understanding the Challenge

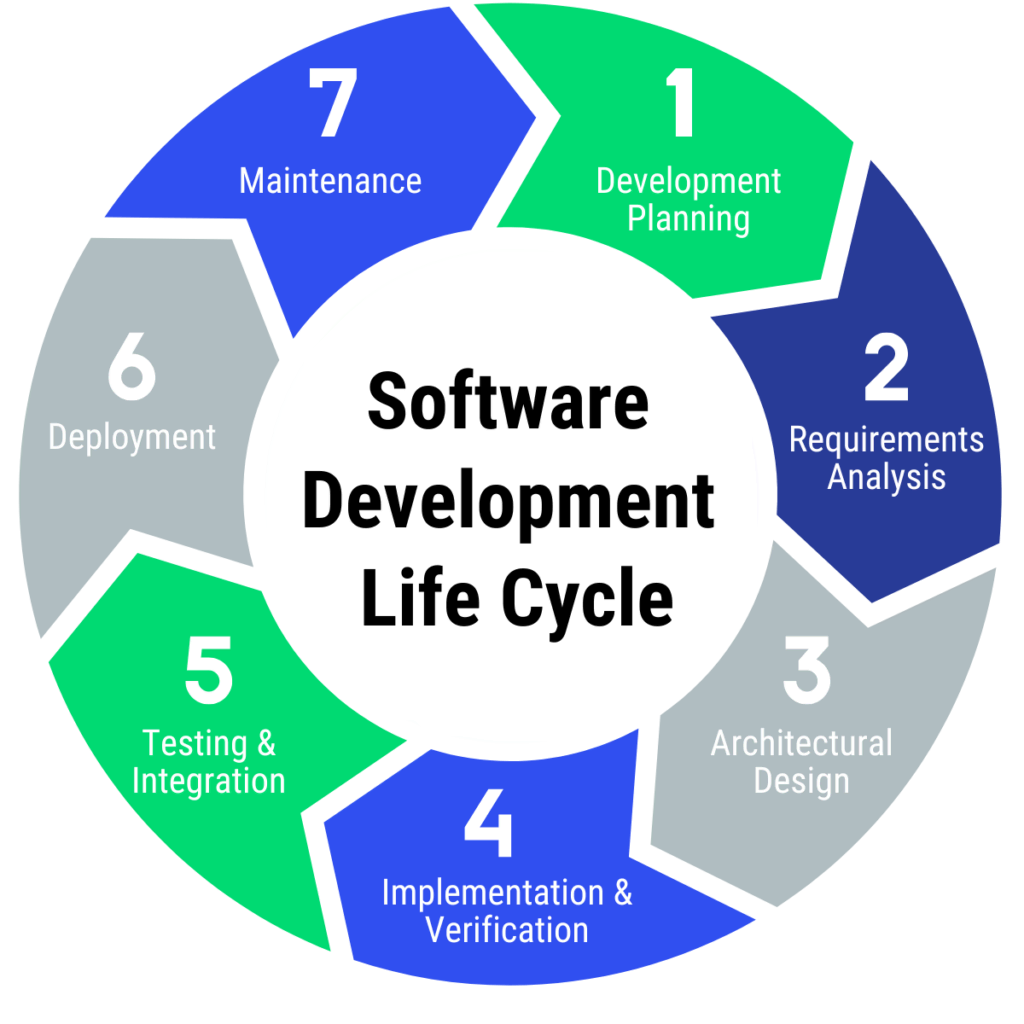

Building software for medical devices is inherently complex due to the high stakes involved. The process differs significantly from other types of software development, such as building websites or games. Medical device software must adhere to strict regulatory standards to ensure safety and efficacy. The primary challenges include:

- Complexity of Development: Medical devices often interact directly with human health, making engineering problems more complex and demanding rigorous validation.

- Inadequate Tooling: The existing software development tools often do not meet the specific needs of medical device development, leading to a gap in compliance.

- Compliance Overhead: The need to run a parallel compliance process adds exponential complexity to the development lifecycle.

Core Challenges and Tensions

The tension between R&D and QA teams stems from their differing responsibilities and approaches:

- R&D Focus: Speed of development, quick iterations, and rapid deployment.

- QA Focus: Ensuring rigorous adherence to procedures, mitigating risks, and validating processes.

This misalignment can lead to process compliance ambiguities and inadequate audit trails, potentially compromising device safety and efficacy.

Best Practices to Bridge the Gap between R&D and Quality Assurance

At the Project Level

- Align Objectives and Processes: Engage R&D and QA teams in developing Standard Operating Procedures (SOPs) and work instructions. Ensure mutual understanding and feasibility of these processes.

- Integrate Compliance into Development: Embed compliance practices into the R&D process through criteria such as the definition of done, which includes quality checks and validations.

- Risk Management: Incorporate risk management practices early in development to identify and mitigate potential product safety and efficacy risks.

At the Story Level

- Detailed Requirements: Include requirements that address user needs and risk evaluations, focusing on safety, security, and interoperability.

- Comprehensive Testing: Develop test cases with good coverage across different test levels (unit, integration, system) to capture all possible use scenarios.

- Traceability and Dependencies: Maintain clear traceability and manage dependencies between different stories and components to facilitate regression testing and integration.

At the Increment Level

- Effective Change Management: Implement robust change management practices to handle new requirements and design changes efficiently.

- Continuous Integration and Delivery (CI/CD): Utilize CI/CD pipelines to automate testing and integration processes, ensuring that each increment maintains the device in a validated state.

- Increment Reviews: Conduct sprint reviews to ensure all completed work meets quality and compliance standards.

At the Release Level

- Configuration Management: Maintain thorough documentation and version control of all configuration items, ensuring that any updates or changes post-release are accurately recorded.

- Formal Design Reviews: Conduct formal design reviews to make go/no-go decisions, ensuring all safety, efficacy, and security requirements are met before release.

- Release Documentation: Generate comprehensive release documents from the source systems to provide a clear and accurate audit trail for regulatory submissions.

Leveraging Technology for Compliance

Tools like Ketryx can significantly enhance compliance and alignment between R&D and QA teams. Ketryx provides:

- Real-Time Traceability: Ensuring all design controls and configurations are traceable and up-to-date.

- Automated Documentation: Generating documents directly from source systems to reduce manual errors and ensure consistency.

- Integrated Risk Management: Managing risks according to standards like IEC 62304 and 14971, tailored to specific hazard types and requirements.

Bridging the gap between R&D and QA is crucial for developing high-quality, compliant medical devices. By following best practices and leveraging advanced tools, medical device manufacturers can streamline their processes, ensure compliance, and ultimately deliver safer and more effective products to the market.

Contact Rook Quality Systems for more information and insights on Empowering the SDLC with Tools to Bridge R&D and Quality.